RFID EM Module Final Functional Verification After Potting | 100% Inspection for ODM Applications

This video presents the final-stage 100% functional verification of an embedded RFID EM module after potting and curing.

Each module undergoes individual EM card and glass tag reading tests to ensure stable detection and product consistency. QC labels are applied after verification, and qualified modules proceed to packaging.

This process is designed for medical devices and customized OEM/ODM embedded RFID applications.

RFID EM Module Potting Process|ODM Customized Embedded RFID Module

This video demonstrates the potting stage of an embedded RFID EM module in the manufacturing process, following antenna soldering and functional verification.

Manual potting is applied based on customer-specific ODM requirements, supporting low-volume, high-mix customized applications and serving as a manufacturing step to enhance overall module reliability during long-term operation.

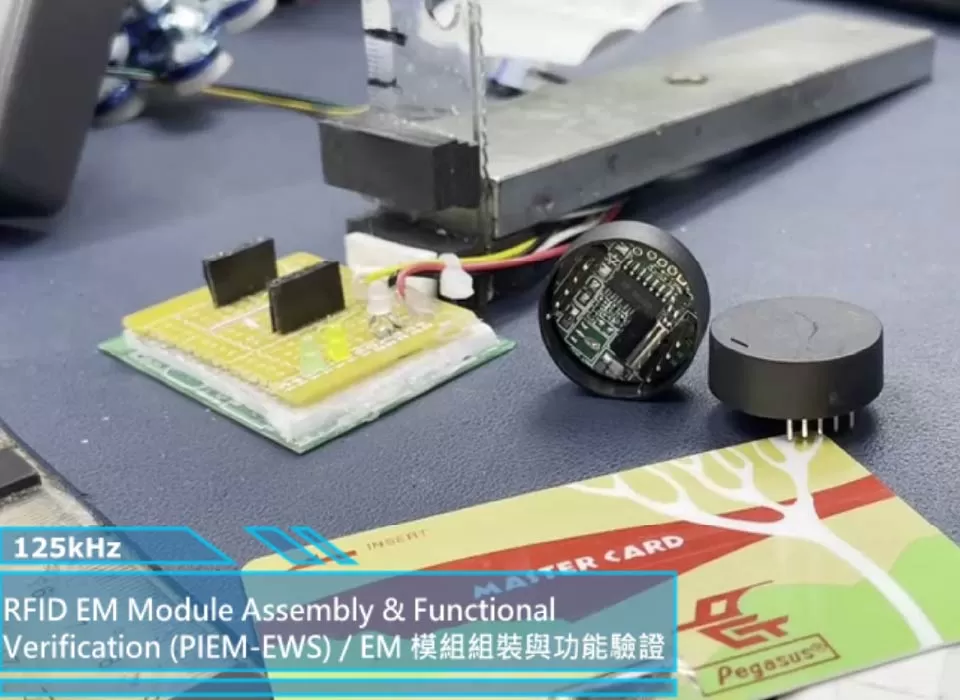

RFID EM Module Assembly & Functional Verification | Embedded RFID Module for Glass Tag Detection

This video presents the antenna soldering and assembly stage of an RFID EM embedded module, followed by first-stage 100% functional verification.

Designed for OEM and medical applications, the module is further subjected to encapsulation and a second-stage full verification to ensure long-term reliability and stable glass tag detection performance.