RFID EM Module Assembly & Functional Verification | Embedded RFID Module for Glass Tag Detection

RFID EM Module Assembly & Functional Verification /Embedded RFID Module for Glass Tag Detection (OEM Application)

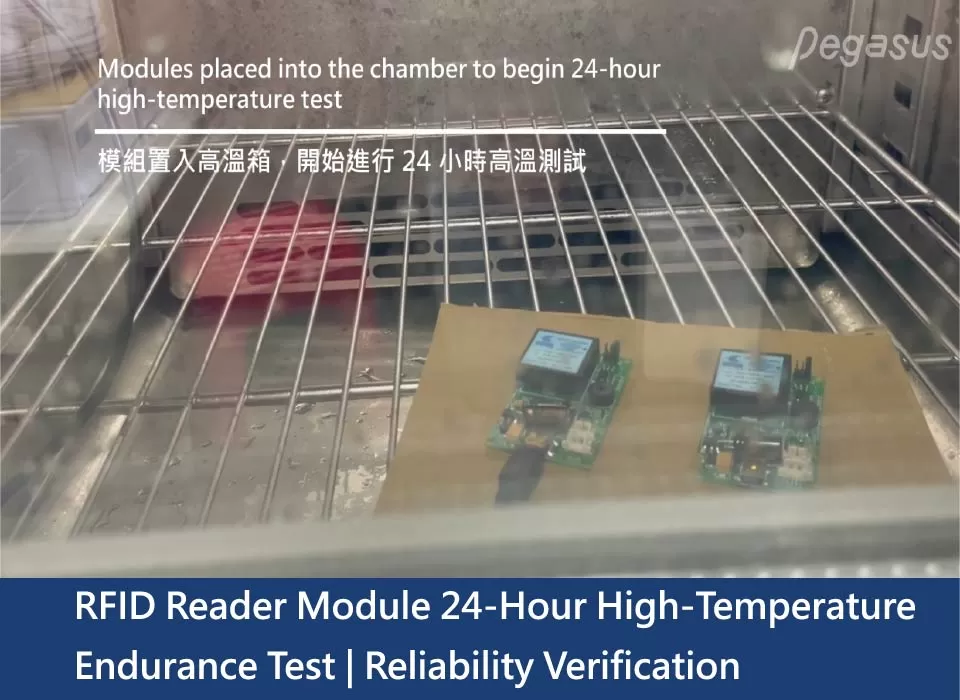

In embedded RFID applications particularly in medical and industrial equipment module reliability and reading consistency directly affect overall system stability and long-term operational performance.

This video presents a partial production-stage process of a customized RFID EM module (PIEM-EWS) developed for OEM applications.

The module is designed to ensure reliable glass tag detection and to support continuous reading operation.

It integrates the RFID circuitry, antenna, and firmware configuration into a compact form factor suitable for embedded system integration.

Production Stages Covered in This Video

rior to the assembly process shown in this video, the module firmware is programmed as part of the standard production workflow.

This video focuses on the antenna soldering and module assembly stage, followed by functional verification performed to confirm antenna connection quality, reading stability, and baseline electrical performance in accordance with design requirements.

Assembly Process Overview

Module assembly is performed in accordance with established work instructions and includes the following key steps:

- Firmware programming (completed prior to assembly)

- Manual solder reinforcement on semi-finished modules

- Antenna soldering and positional adjustment

- Structural preparation prior to encapsulation

100% Functional Verification Process

Each module undergoes multi-stage 100% functional verification throughout the production process.

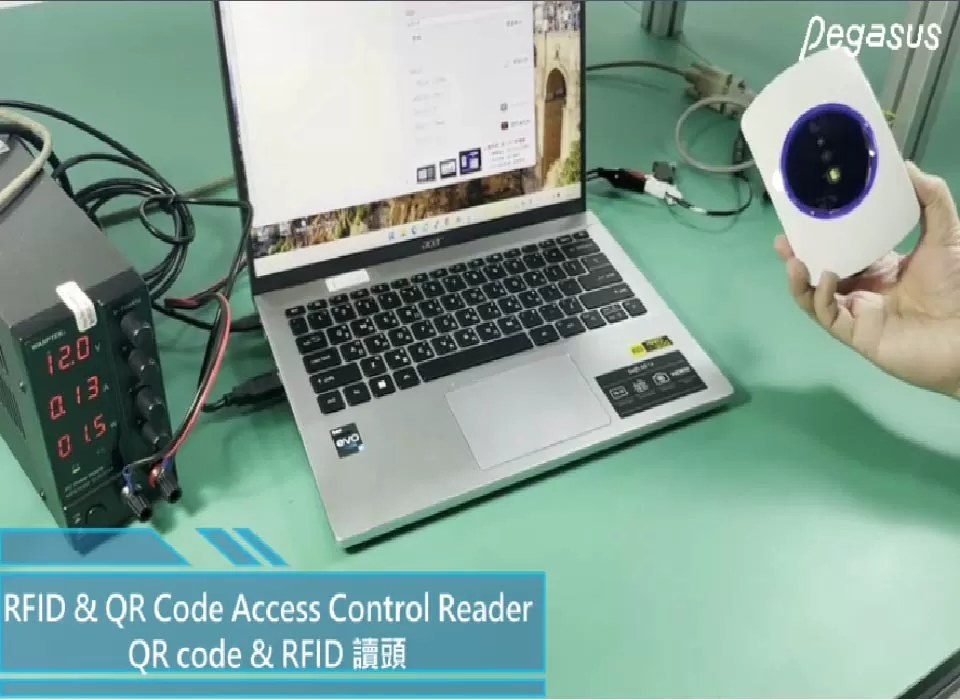

The verification items demonstrated in this video include:- Continuous reading function verification

- Output format validation (Wiegand 26-bit, ASCII, hexadecimal / 14-digit code)

- Current consumption measurement under standby and active reading conditions

- Glass tag detection testing (mandatory) to ensure stable reading performance within specified distance limits

Subsequent Production Stages and Final Verification

After completion of antenna assembly and first-stage verification, the module proceeds to a potting and encapsulation process, which enhances mechanical protection and long-term operational stability.

Following encapsulation, each module undergoes a second-stage 100% functional verification, confirming that post-encapsulation reading performance, output formats, and electrical characteristics remain within defined specifications.

Modules are packaged and shipped only after successfully passing all verification stages.

Due to production scheduling and curing time requirements, the encapsulation and final shipment stages are not included in this video. However, all production processes are executed in full accordance with documented work instructions.

Engineering Value for OEM and Medical Applications

The processes demonstrated in this video reflect a production philosophy centered on process control, traceability, and reliability, making the module particularly suitable for:

- Medical equipment incorporating identification functionality

- Industrial devices requiring long-term stable operation

- OEM projects where RFID modules are deeply embedded within proprietary systems