RFID Module Lifecycle Management | Long-Term Supply Stability & EOL Risk Analysis

FID Module Lifecycle Management|Why It Matters More Than Price in Procurement

Introduction

As RFID technology becomes widely adopted in healthcare, manufacturing, transportation, finance, and retail, customers are no longer evaluating solutions solely on “functionality” or “price.” What truly determines the return on investment (ROI) is whether the system can operate reliably over the long term. This is why RFID module lifecycle management (Product Life Cycle, PLC) has become a critical factor in international procurement decisions.

This article explains why PLC is essential for RFID systems, highlights common risks, and outlines how suppliers and enterprises can address them.

Why Product Lifecycle Management Is Crucial

- Long usage cycles: Healthcare and manufacturing systems typically operate for 10+ years. If modules are discontinued, the entire system may become unsustainable.

- High compliance costs: Replacing a key component may require recertification (CE, FDA, or industrial safety), which often costs more than the original purchase.

- Maintenance and spare part challenges: Using different components in different batches complicates maintenance and increases inventory costs.

- Business risks: Discontinuation can cause project delays, production downtime, penalties, and even loss of customers.

Common Procurement Concerns

Mature enterprise customers often raise the following questions during tenders or sourcing discussions:

- Which MCU/IC is used in the module? What is its PLC plan?

- Can the supplier guarantee 8–10 years of supply?

- If the main chip is discontinued, is there a replacement strategy?

- Does the supplier provide an EOL (end-of-life) notice period and mitigation plan?

These concerns show that customers are not only asking, “Can it work?” but also “Can it work for the long term?”

Supplier Strategies for Lifecycle Assurance

Professional RFID module suppliers should integrate lifecycle management principles from the design stage:

1. Long-life component selection

Use industrial-grade MCUs and ICs with long supply cycles, avoiding short-lived consumer-grade parts.

2. Alternative design planning

Build in pin-to-pin and functional compatibility so replacement parts can be integrated quickly if the original component is discontinued.

3.In-house R&D and customization

Since the module is developed in-house, if a key component is discontinued, it can be immediately replaced with an alternative part. This prevents full product discontinuation and demonstrates the flexibility and resilience of an in-house design approach.

4.Long-term supply commitment

Provide 8–10 years of product availability and offer extended spare part and maintenance services, giving customers confidence for deployment.

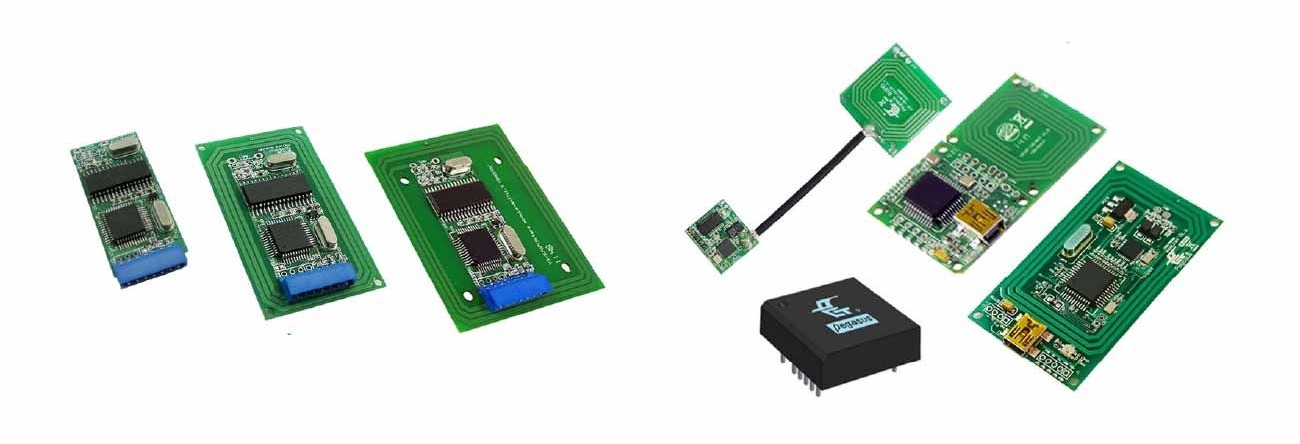

RFID Card Reader / RFID Reader Writer

Balancing Cost and Risk

- Short-term savings vs long-term stability: Choosing cheaper, short-lifecycle components reduces upfront CAPEX but increases OPEX and replacement risks.

- Warranty and SLA: Compare suppliers’ warranty coverage, EOL policies, and service-level agreements (SLA). These directly impact the total cost of ownership (TCO).

- Return on investment (ROI): Only modules that can reliably operate for a decade or more align with enterprises’ long-term investment plans.

Global Market Trends

According to MarketsandMarkets, the global RFID market is projected to exceed USD 40 billion by 2030, with healthcare and manufacturing driving the fastest growth. These industries are particularly strict about lifecycle assurance. Suppliers that cannot provide long-term guarantees are often excluded from procurement lists.

In international tenders, product lifecycle assurance has already become more important than price alone.

Pre-Deployment Checklist for Enterprises

Before adopting an RFID system, enterprises should verify:- Does the datasheet specify MCU/IC type and lifecycle plan?

- Is there an EOL notification period (minimum 12 months)?

- Are alternative components or multi-source strategies available?

- Does the supplier provide firmware updates and version control?

- Is there an option for extended spare parts or long-term service agreements?

Conclusion

RFID module lifecycle management is not just a technical issue—it is a business investment issue. The ability to provide long-term supply commitments and alternative designs directly impacts ROI and operational stability.

For customers, lifecycle management should be considered just as important as functionality and price when selecting a supplier.

For suppliers, having in-house R&D and customization capabilities—and offering documented lifecycle commitments—enables them to stand out in the highly competitive RFID market.

📚If you are looking for RFID modules and application solutions, we welcome you to contact us.

We provide RFID modules, readers/writers, and complete technical integration support to help you accelerate project development and deployment planning.

Click the contact button below, and our representative will get in touch with you shortly.