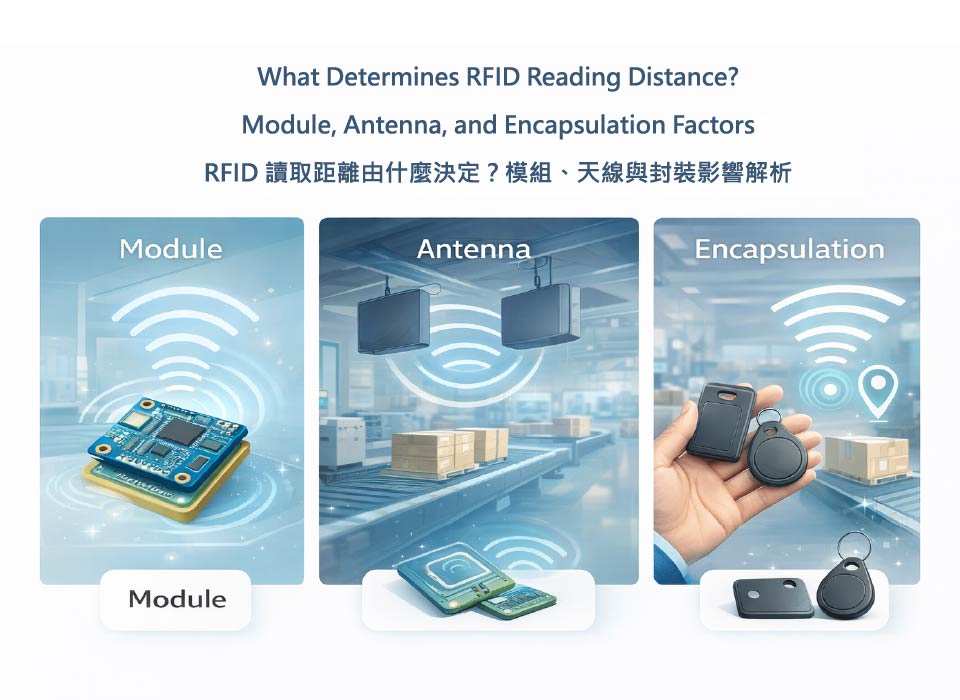

What Determines RFID Reading Distance? Module, Antenna, and Encapsulation Factors

In RFID projects, reading distance is often considered one of the most important performance indicators. However, in real-world implementations, reading distance is not defined by a single component specification, but rather by the combined outcome of overall system design.

Even when using the same RFID chip or module, actual reading distance may vary significantly depending on antenna design, encapsulation methods, and installation conditions.

Why RFID Reading Distance Is Not Defined by a Single Specification

RFID reading distance is influenced by multiple factors, including RF module performance, antenna configuration, encapsulation materials, and the operating environment. Comparing module specifications alone is often insufficient to predict real system behavior.

Impact of RFID Modules on Reading Distance

RF Circuit Design and Output Performance

RF circuit design, output power, and receiver sensitivity of an RFID module directly affect achievable reading distance. In embedded applications, trade-offs between power consumption, stability, and RF performance are unavoidable.

Communication Interface and System Integration

Stability of power supply and communication interfaces can indirectly impact effective reading distance during actual operation. Unstable system integration may reduce performance despite suitable module specifications.

Antenna Design: A Critical Factor in RFID Reading Distance

Antenna Size and Form Factor

Antenna size and shape are closely related to operating frequency. Excessive miniaturization often leads to reduced reading distance, especially in space-constrained devices.

Antenna Orientation and Installation Position

Antenna orientation and installation angle significantly influence the effective reading zone. Incorrect installation frequently causes greater distance loss than module limitations.

Effects of Encapsulation and Potting on RFID Reading Distance

Dielectric Properties of Encapsulation Materials

Encapsulation and potting materials may alter antenna resonance characteristics due to their dielectric properties, thereby affecting actual reading distance.

Why Final Verification Is Required After Potting

In OEM / ODM projects, final functional verification after potting is essential to ensure consistent reading performance under real operating conditions.

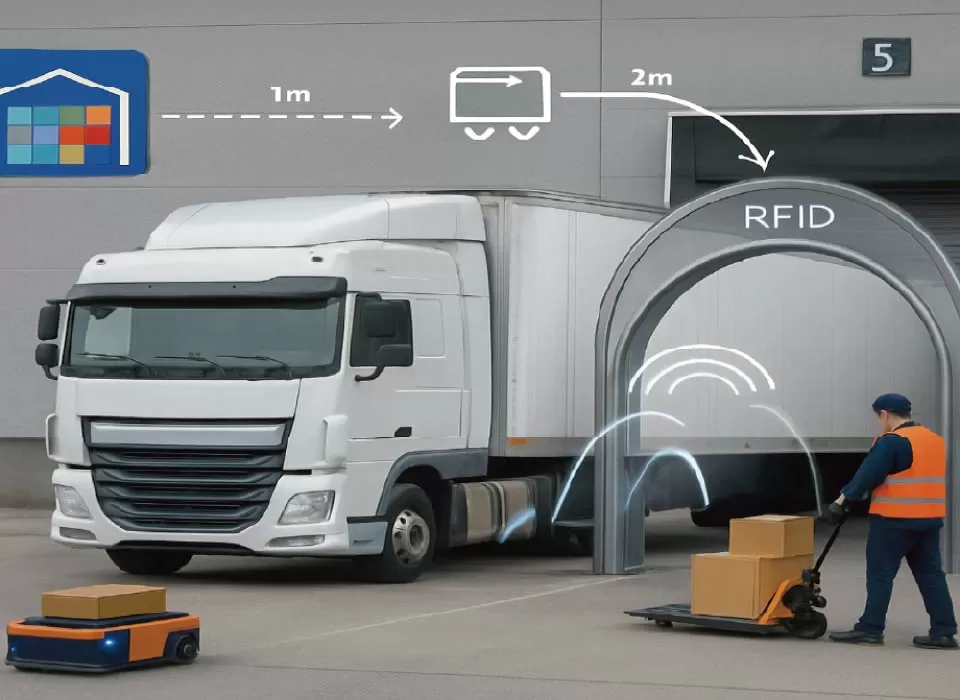

Environmental Factors Affecting RFID Reading Distance

Metal and Liquid Environments

Metal and liquid surfaces absorb or reflect RF energy, commonly reducing effective reading distance.

Electromagnetic Interference and Site Conditions

Motors, inverters, and other wireless devices in industrial environments may also impact RFID system performance.

How to Properly Evaluate RFID Reading Distance in Projects

System-Level Evaluation Approach

Reading distance should be validated under real application conditions, rather than relying solely on laboratory measurements.

Why OEM / ODM Projects Focus on Overall Design

For mass production, stable and repeatable reading distance is often more critical than peak distance values.

Conclusion: RFID Reading Distance Is a System-Level Outcome

RFID reading distance is determined by the combined effects of module design, antenna configuration, encapsulation, and operating environment. For OEM / ODM and long-term deployments, system stability should take precedence over isolated distance specifications.

Actual system planning should be evaluated based on project environment, application requirements, regulatory constraints, and overall system architecture. This article provides general technical decision logic and selection references to help clarify key factors affecting RFID reading distance in real-world implementations.