An electronics manufacturing service (EMS) provider for a U.S. automotive parts brand, mainly producing PCB modules and control units, with a monthly capacity exceeding 200,000 units. Due to high order volumes and tight lead times, production processes require both efficiency and transparency. Previously, the factory relied on paper-based work orders and manual barcode scanning, which led to slow WIP transfers, frequent work order errors, and negative impact on production scheduling and quality control.

Pain Points

- Difficult WIP Tracking: Records were often lost during process handovers, causing delays.

- High Work Order Error Rate: Paper-based records frequently caused “skipped steps” or repeated operations.

- Inaccurate Machine Maintenance: Lack of data meant maintenance was mostly reactive.

- Low Operational Visibility: Supervisors could not easily monitor shop floor status in real time.

RFID Solution

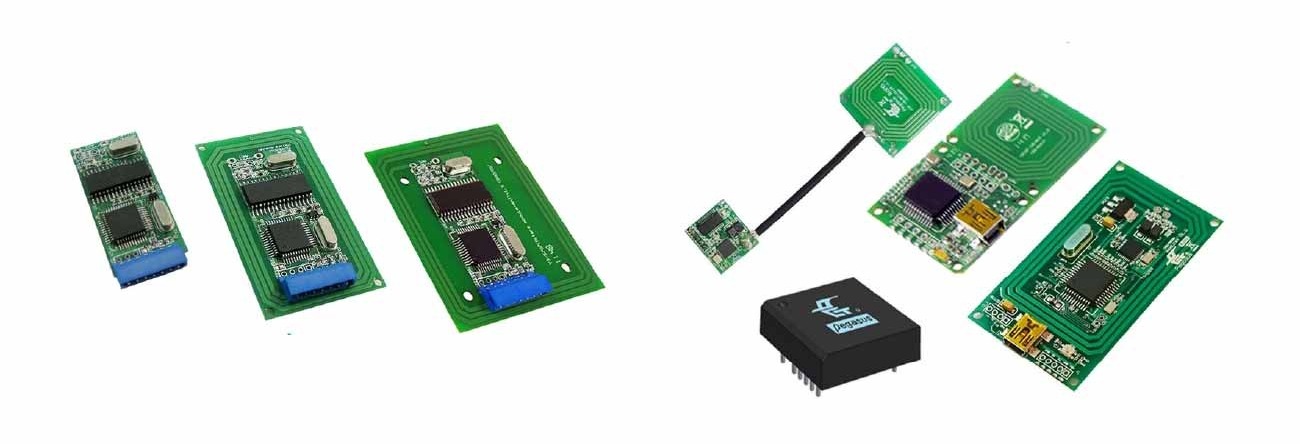

The factory partnered with Pongee to implement 13.56MHz Mifare RFID modules, integrated with a Manufacturing Execution System (MES), with the option to connect to ERP systems:

- Work Order RFID Tagging: Each work order and WIP pallet was tagged with RFID to prevent loss.

- Station-Level Readers: RFID readers installed at each workstation automatically recorded work orders as they passed.

- Machine Maintenance Patrol: Each machine is equipped with an RFID card. After inspection or maintenance, technicians scan the card to automatically log the time for easy tracking of maintenance status.

- Real-Time Data Integration: Information was updated instantly into the MES, enabling supervisors to track progress through dashboards.

※Mifare is a registered trademark of NXP B.V.

Mifare DESFire is a registered trademark of NXP B.V.

Mifare Ultralight is a registered trademark of NXP B.V.

FeliCa is a trademark of Sony Corporation.

Results

- WIP tracking efficiency significantly improved, enhancing workflow continuity.

- Work order errors substantially reduced, leading to fewer reworks.

- Unplanned downtime effectively lowered, with more accurate maintenance scheduling.

- Supervisors could track progress in real time and adjust schedules more quickly.

Extended Value

- Quality Traceability : RFID work order records provide complete product history.

- Data-Driven Decisions : Bottlenecks are digitized, helping improve production processes.

- Operator Accountability : Linking operator cards with work orders ensures clear responsibility.

- OEM/ODM Flexibility : Work order systems can be customized to meet customer requirements.

Global Trend Insight

According to McKinsey, the smart manufacturing market in Latin America is growing at a CAGR of 13%. Mexico, due to its proximity to the U.S., has become a major hub for automotive parts manufacturing. However, most factories still rely heavily on barcodes, and RFID adoption remains low, showing strong growth potential.

FAQ

Q1:Does RFID need to fully replace barcodes?

A:No. RFID and barcodes can run in parallel, enabling gradual adoption.

Q2:Can RFID systems integrate with existing Manufacturing Execution Systems (MES)?

A:Yes. Pongee RFID modules support multiple communication protocols and can be embedded into existing MES systems.

Q3:Beyond work order and WIP tracking, where else can RFID be applied?

A:Applications include machine maintenance, finished goods warehousing, and tool management helping build a more complete smart factory.

Q4:Will the benefits in the case study be fully replicated?

A:Actual results may vary depending on factory size, process design, and implementation scope. The case study data is for reference only, and outcomes should be adjusted to fit each factory's situation.

📚

If you are a system integrator or distributor looking for RFID modules and application solutions for the manufacturing, factory, or electronics industry, feel free to contact us.

We provide RFID modules, readers, and comprehensive technical integration recommendations to help you accelerate project development and implementation planning.