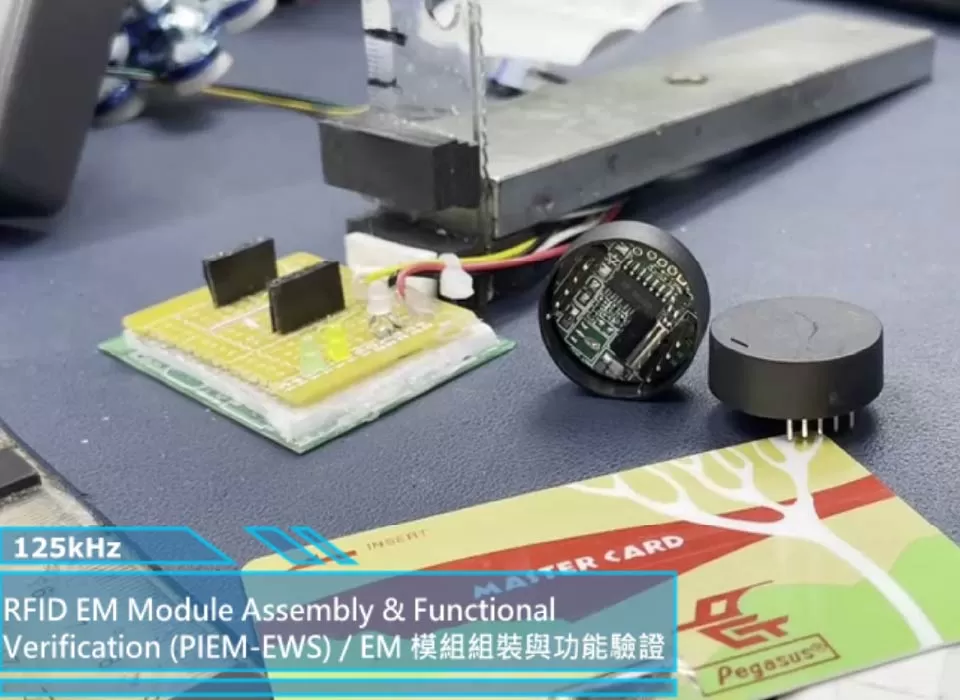

RFID EM Module Final Functional Verification After Potting | 100% Inspection for ODM Applications

Why Final Functional Verification Is Required for RFID EM Modules

In embedded RFID applications, a final-stage 100% functional verification is required after potting and full curing to ensure that the encapsulation process has not affected antenna characteristics, detection performance, or electrical stability.

This final verification serves as a critical quality gate before shipment, ensuring consistent and reliable performance in real-world applications.

Position of Final Verification in the Manufacturing Process

The final verification shown in this video is performed after the following steps are completed:

- Antenna soldering and electrical connection

- Two-stage functional verification (bare module and after housing assembly)

- Potting and full curing of the module

Verifying the module at this stage ensures functional integrity under its final encapsulated condition before packaging.

Final 100% Functional Verification Items

Each RFID EM module undergoes individual verification, including:

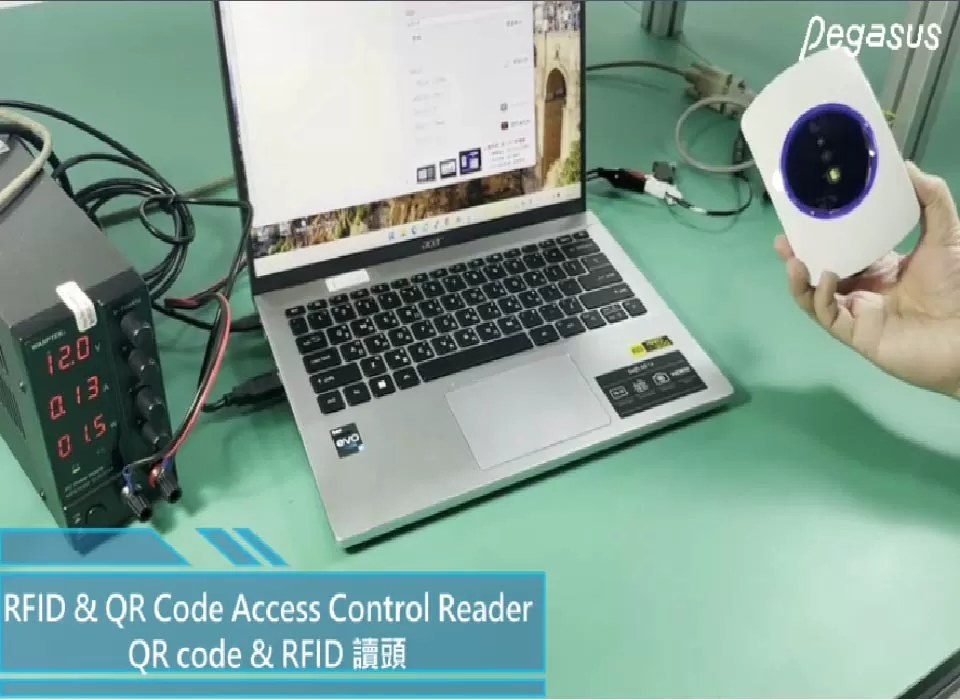

- EM card reading test to confirm stable detection under normal operating conditions

- Glass tag reading test to validate reliable detection for compact and embedded application scenarios

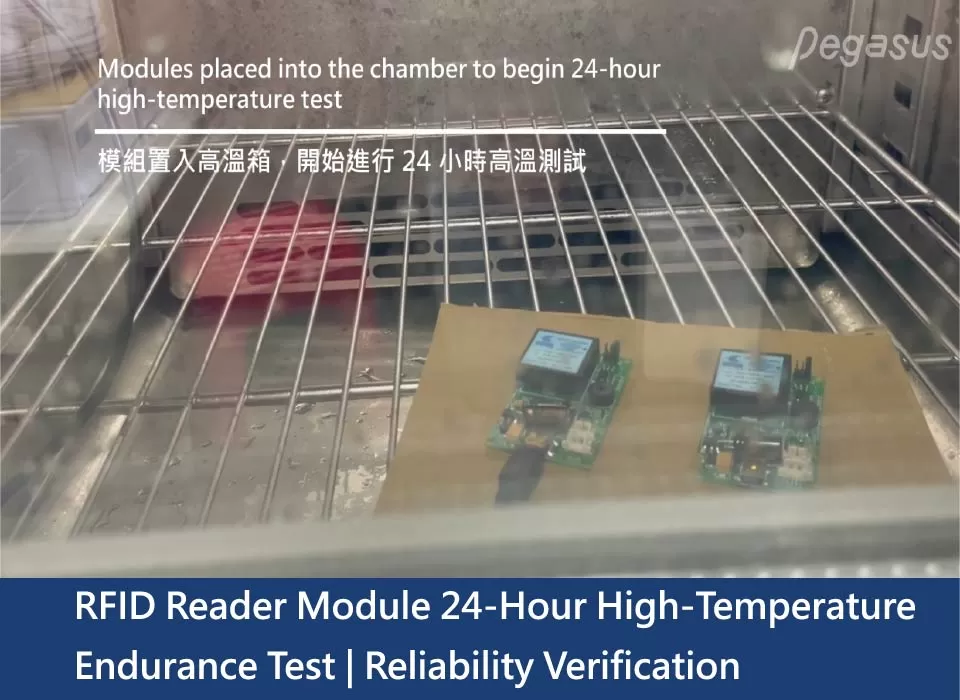

Why Verification Is Required After Potting

While potting enhances environmental protection and mechanical stability, it may also influence:

- Antenna impedance and detection behavior

- Long-term operational stability

- Consistency across different application environments

Therefore, final verification after curing is an essential step to ensure product quality and reliability.

QC Labeling and Packaging Process

Modules that pass the final verification will:

- Receive a QC label for quality identification

- Be placed into dedicated trays by batch

- Proceed to packaging and shipment

This ensures that every shipped module has completed the full manufacturing and verification process.

OEM / ODM Application Value

By implementing a structured workflow of assembly, multi-stage verification, potting, final verification, and shipment, OEM/ODM

projects benefit from improved production consistency, reduced failure risk, and long-term reliability for embedded RFID modules

used in medical and industrial applications.